As architecture delves into its history before the digital age, building creation was an art meticulously crafted by hand.

Architects transferred their visions onto paper using pencils, ink, rulers, and compasses, gradually developing every detail through a series of hand-drawn plans and sketches. This approach required not only technical skill and precision but also a deep understanding of materials, construction principles, and, above all, spatial thinking. Every line on paper was the product of extensive thought and planning, and modifications often required the creation of new drawings, making the process time-consuming and laborious.

In contrast, contemporary architectural practice is permeated with digital technologies. Today, architects use advanced software such as CAD and BIM that allow not only faster drawing and modeling but also the integration of a large amount of data about the project, from materials and construction techniques to simulations of energy efficiency and environmental impact. These digital tools enable architects to quickly adjust their designs, experiment with different options, and easily collaborate with other experts.

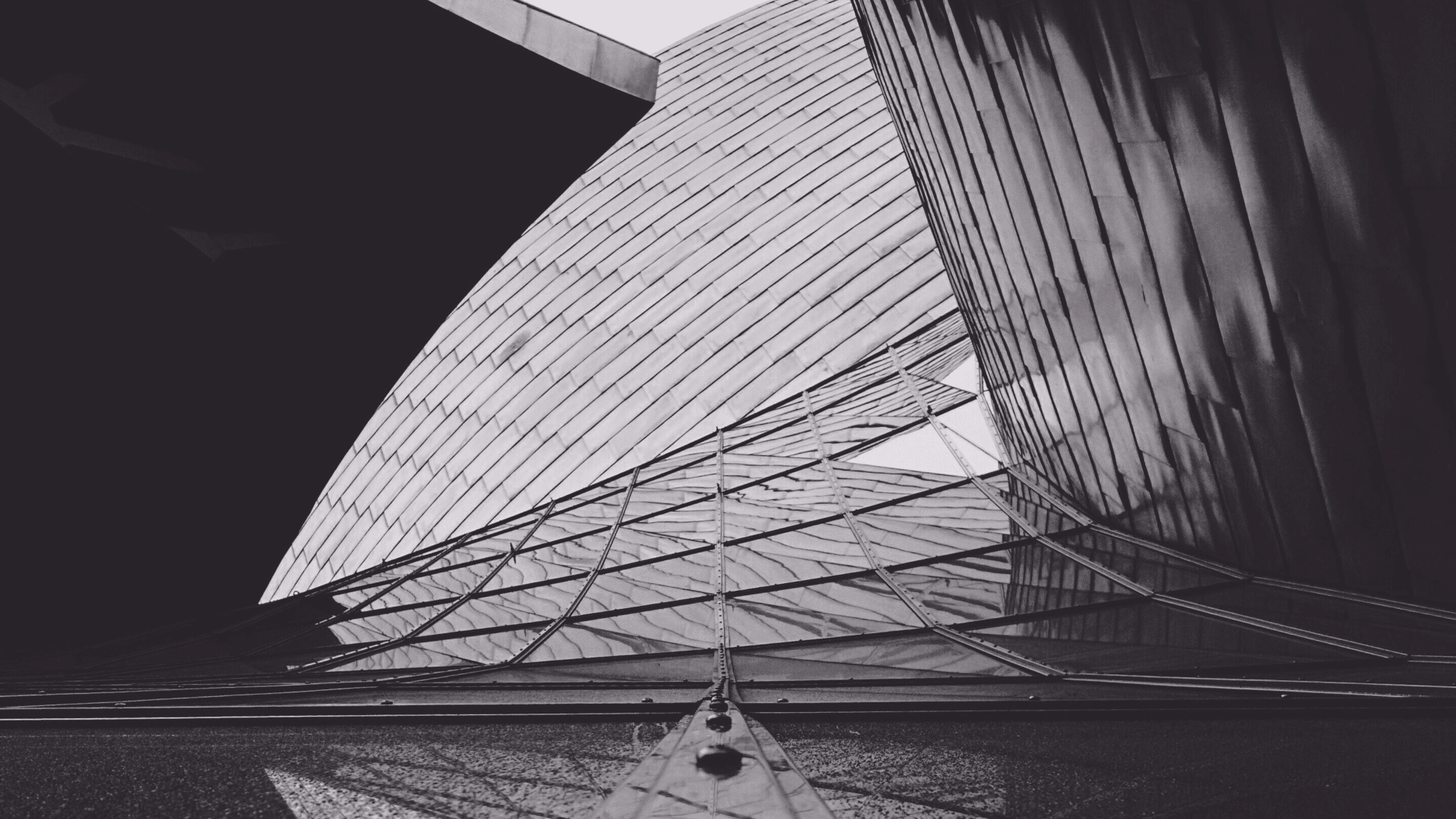

One of the key advantages of digital tools is their ability to create detailed three-dimensional models, which offer not only a visually richer representation of the project but also a deeper understanding of spatial relationships, light effects, and the functionality of the building. These models can be used to produce realistic visualizations and animations, allowing clients to “walk” through their future homes or business spaces before anything is built. Such immersiveness was unimaginable in the era of hand drawing.

Experience through VR and AR

Virtual and augmented reality have opened new ways of interacting with spatial design. Architects can now guide clients through yet unbuilt spaces, allowing them to experience the dimensions, materials, and light in a way that was previously unimaginable. This technology not only transforms project presentations but also allows architects to experiment with design in virtual space, testing and adjusting elements before they become part of the real world.

Comparing hand drawing and digital design, it is clear that each approach has its unique advantages. Hand drawing fosters a deep connection with the project and develops skills of contemplation through drawing, while digital design offers speed, efficiency, and the ability to explore more complex ideas. Digital tools also facilitate the integration of sustainable practices into design, enabling architects to precisely analyze how buildings use resources, how they behave in different climatic conditions, and how they can minimize their environmental footprint.

Technology has also enabled the development of new materials and construction methods, such as 3D printing, opening the door to innovations in design and construction. These advancements mean that today’s architects face not only the question of how to build structures but also the challenge of redefining what buildings can be in the context of contemporary technological and environmental possibilities.

Prototypes and Models

One of the most common applications of 3D printing in architecture is prototypes and models. This technology allows for quick and precise production of physical models of buildings and urban projects. Unlike hand-crafted models, which require time and skill, 3D printed models can be produced overnight, enabling architects to quickly test and present their ideas.

Customized Facade Elements

The first 3D printed concrete house in the Netherlands is part of a project called “Project Milestone” realized in Eindhoven. The project is the result of collaboration between Eindhoven University of Technology, Dutch construction companies such as Van Wijnen, and other industrial partners.

Each house in the project has a unique design and is made using advanced 3D printed concrete technology. The innovation allows for the creation of complex shapes and structures, which are not only aesthetically appealing but also functionally superior in terms of insulation and sustainability.

The project involving the construction of a facade using 3D printed concrete panels highlights the possibility of creating complex, customized architectural elements. These panels not only improve the aesthetics of the building but are also optimized for energy efficiency, helping control the flow of natural light and thermal insulation. The project shows how 3D printing can contribute to sustainable design, allowing for the creation of unique forms that could not be easily realized with traditional methods.

Sustainable Buildings

In Mexico, a project for affordable housing uses 3D printing to build homes for low-income communities. This approach allows for rapid construction, cost reduction, and waste minimization. The houses are designed to be functional, durable, and energy-efficient, using materials that are locally available or recycled. Besides addressing the housing problem, the project also demonstrates the potential of 3D printing in producing customized homes that can adapt to specific climatic and social conditions of the region.

The initiative to build affordable housing units using 3D printing is often the result of collaboration between nonprofit organizations, technological startups, and local authorities. One of the well-known examples is a project conducted by New Story, a nonprofit organization, in collaboration with ICON, a company specializing in 3D printing technology in construction.

Projects are designed to meet the specific needs of communities, taking into account local climate conditions and cultural aspects. ICON’s technology uses a robotic 3D printer that extrudes concrete mixture layer by layer, creating strong and durable walls.

Complex Structural Elements

The first 3D printed pedestrian bridge was built in the Castilla-La Mancha park in Alcobendas, Madrid. The project was developed by the Institute for Advanced Architecture of Catalonia (IAAC) and various local partners.

In Spain, the construction of a bridge using 3D printed concrete is an example of how this technology can be applied to infrastructure projects. The bridge not only demonstrates the structural strength and durability of materials produced by 3D printing but also the aesthetic value that can be achieved through complex designs. This project highlights the potential of 3D printing in the construction of public infrastructure, offering innovative solutions that are both functional and visually appealing.

The bridge was designed using parametric design tools that allow for the optimization of materials and structural efficiency. It was executed using a specific 3D printer for concrete, enabling the realization of a complex structure that demonstrates the potential of 3D printing in the construction of infrastructure projects.

Ultimately, the transition from hand drawing to digital design has not only changed the tools architects use but has also expanded the boundaries of architectural creativity and innovation. As technology continues to advance, so will architecture continue to evolve, adopting new methods, materials, and ideas to create spaces that not only meet human needs but also inspire human imagination.